Understanding Industrial Laser Cleaning: What It Is and Why It Matters

LL

Understanding Industrial Laser Cleaning

Industrial laser cleaning is a technological advancement that has gained significant attention in recent years. As industries strive for more efficient, environmentally friendly, and precise cleaning solutions, laser technology has emerged as a leading option. But what exactly is industrial laser cleaning, and why does it matter? This blog post will delve into these questions, exploring the mechanics and benefits of this innovative cleaning method.

What Is Industrial Laser Cleaning?

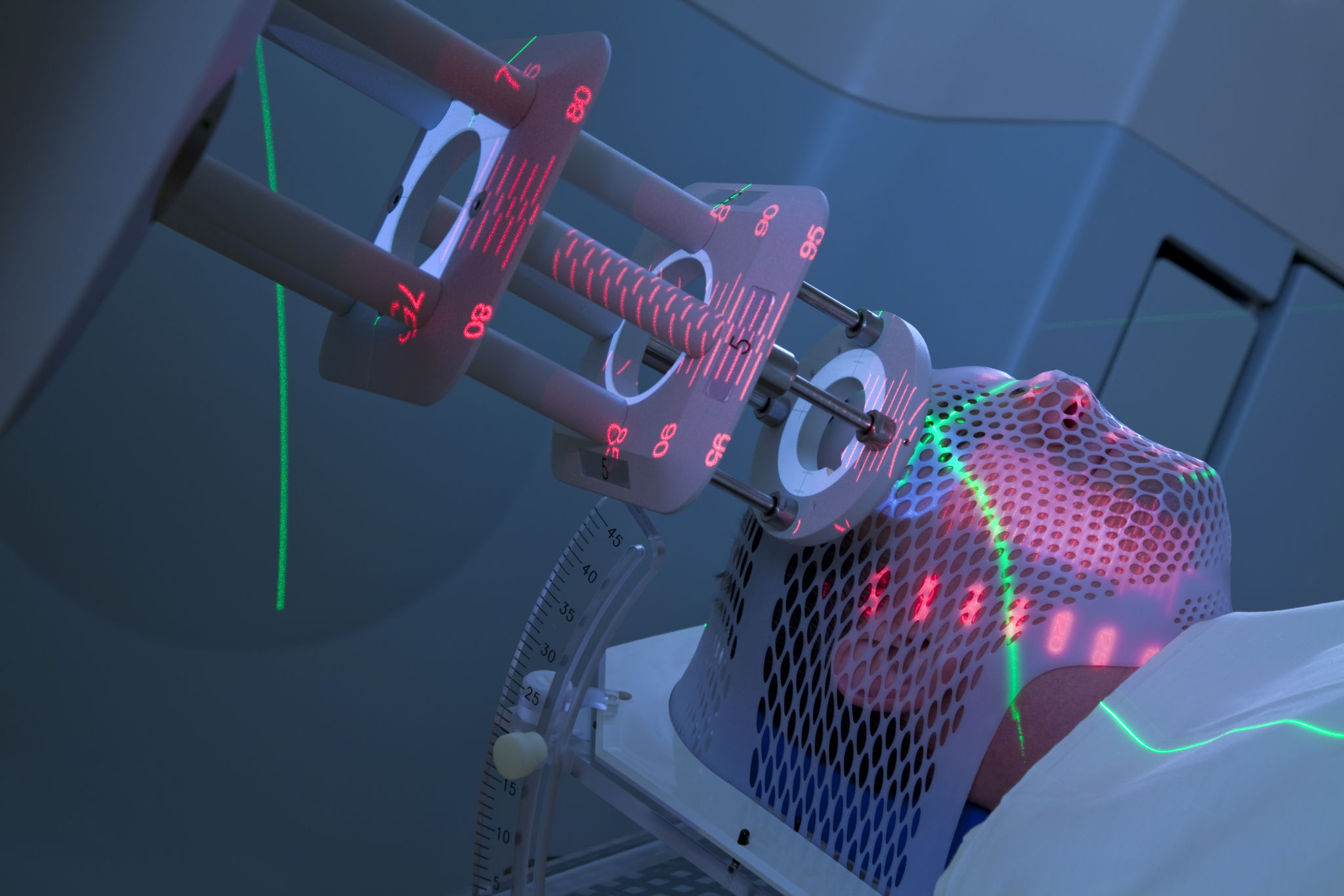

At its core, industrial laser cleaning is a process that utilizes laser beams to remove contaminants, coatings, or residues from surfaces. Unlike traditional cleaning methods that often involve chemicals or abrasive materials, laser cleaning operates by directing a concentrated beam of light onto a surface. This process effectively vaporizes or breaks down the unwanted material without damaging the underlying surface.

The technology behind laser cleaning is based on the principle of "laser ablation," where the laser beam's energy disrupts the bonds of the contaminant particles. This method is not only precise but also adaptable to various applications, from delicate conservation projects to heavy-duty industrial maintenance.

Benefits of Laser Cleaning

One of the most notable advantages of laser cleaning is its environmental friendliness. Since it does not require chemical solvents or produce harmful waste, it significantly reduces the environmental impact associated with industrial cleaning processes. Moreover, laser cleaning is often more energy-efficient than traditional methods.

Another key benefit is its precision. Laser cleaning allows for targeted removal of unwanted materials without affecting the surrounding area. This makes it ideal for applications where high precision is necessary, such as in aerospace or electronics industries.

Applications of Laser Cleaning

Laser cleaning is versatile and can be applied across various industries. In the automotive sector, it’s used for removing paint and rust from car parts. In aerospace, it's crucial for cleaning turbine blades and engine parts without compromising their structural integrity. Additionally, it plays a vital role in heritage conservation by removing dirt and pollutants from historical artifacts and monuments.

- Automotive Industry: Paint and rust removal from metal parts.

- Aerospace: Cleaning of engine components and turbine blades.

- Heritage Conservation: Delicate cleaning of historical artifacts.

The Future of Laser Cleaning

As technology continues to advance, the capabilities and applications of industrial laser cleaning are expected to expand even further. Innovations in laser technology may lead to faster, more efficient systems capable of handling larger volumes or more complex tasks. This evolution will likely enhance its appeal across different sectors, driving wider adoption.

Furthermore, as industries become more environmentally conscious, the demand for sustainable cleaning solutions will continue to rise. Laser cleaning stands out as a leading option due to its efficiency and low environmental impact. It aligns well with global efforts to reduce carbon footprints and promote eco-friendly industrial practices.

Conclusion

In summary, industrial laser cleaning represents a significant leap forward in surface treatment technologies. Its precision, efficiency, and eco-friendliness make it a powerful tool in numerous applications. As industries evolve and environmental regulations become stricter, understanding and adopting technologies like laser cleaning will be crucial for maintaining competitiveness and sustainability in the global market.