Laser Coating Removal: How It Compares to Traditional Methods

LL

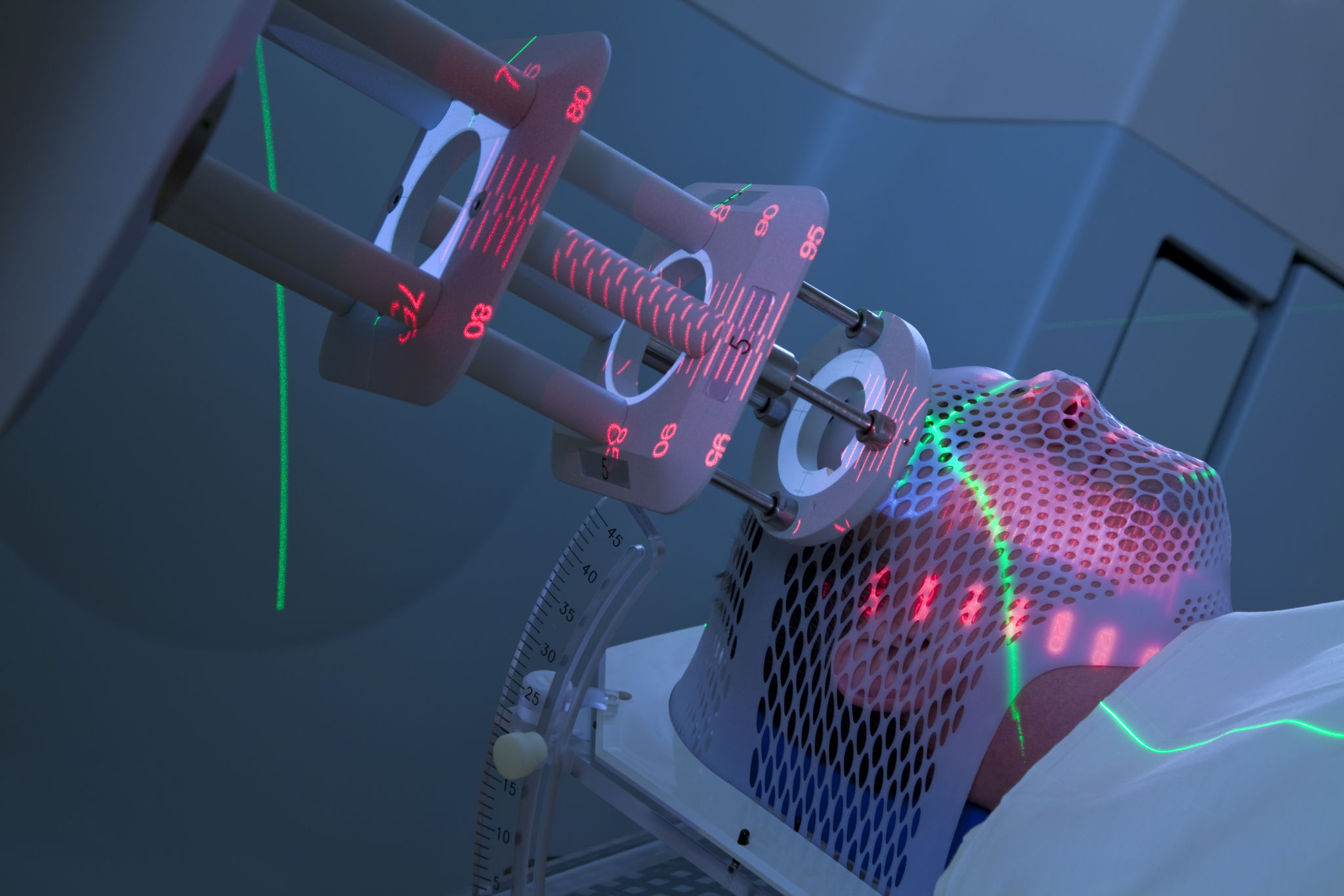

Understanding Laser Coating Removal

Laser coating removal is an innovative technique that uses concentrated laser beams to strip coatings from surfaces. This method is gaining popularity in various industries, including automotive, aerospace, and manufacturing, due to its precision and environmental benefits. By using laser technology, coatings can be removed without damaging the underlying material, which is a significant advantage over traditional methods.

Traditional Coating Removal Methods

Traditional methods for removing coatings include mechanical, chemical, and thermal techniques. Mechanical methods involve sanding, grinding, or abrasive blasting, which can be labor-intensive and may damage the substrate. Chemical stripping uses solvents or acids to dissolve the coating but can pose environmental and health risks. Thermal methods, like heat guns or ovens, can effectively remove coatings but often result in substrate damage due to high temperatures.

Advantages of Laser Coating Removal

Laser coating removal offers several advantages over traditional methods. It provides precision and control, allowing operators to target specific areas without affecting surrounding surfaces. The process is also eco-friendly since it does not require chemicals or produce hazardous waste. Additionally, laser systems can be automated for increased efficiency and consistency in large-scale operations.

Cost Considerations

While the initial investment for laser coating removal equipment can be high, it often proves cost-effective in the long run. The reduced labor costs, lower consumable expenses, and minimal waste disposal fees contribute to overall savings. Traditional methods may seem cheaper initially but often incur higher costs over time due to substrate damage and environmental compliance.

Applications Across Industries

Laser coating removal is versatile and can be applied to various materials like metals, plastics, and composites. In the aerospace industry, it is used for paint stripping aircraft components without compromising their integrity. The automotive sector benefits from laser technology in removing rust and old paint layers efficiently. Furthermore, it is employed in manufacturing for cleaning molds and tools.

Challenges and Limitations

Despite its many benefits, laser coating removal also has limitations. The process may be slower than some traditional methods for large surface areas. Additionally, certain coatings or substrates may not respond well to laser treatment, requiring alternative solutions. Operators need specialized training to ensure safe and effective use of laser equipment.

Future of Laser Coating Removal

As technology advances, laser coating removal is expected to become even more efficient and accessible. Innovations in laser systems aim to increase speed and adaptability to various materials and coatings. This evolution could make laser techniques a primary choice for industries seeking sustainable and precise coating removal solutions.

Conclusion

In conclusion, laser coating removal offers a modern alternative to traditional methods with numerous advantages such as precision, eco-friendliness, and cost-effectiveness. As industries continue to prioritize sustainability and efficiency, the adoption of laser technology is likely to grow. While it may not replace all traditional methods entirely, it provides a valuable tool for specific applications where precision and substrate protection are paramount.